Leather Dye for Leather Crafters

Before choosing the leather dye to use, you should well know the different types of leather dye existing, when and where you could use them. Enjoy this five-minute reading for an overview on leather dyes for leather crafters.

Leather has always been a fascinating materials for many people, so if you are passionate with leather probably you’ve heard a lot about what is leather dye and how natural leather is treated to achieve your favourite color and finishing. The leather dyes have always interested everyone who has a leather article at home, then how to color a leather object, be it a leather sofa, a leather article or a car furniture. However, we must distinguish different fields of use for which leather dyes have been developed, as there are different products that are developed according to the use that must be made of them.

For Private

Do-It-Yourself has become more and more common nowadays, therefore many individuals are searching for leather dyes that can allow to paint or repair the precious leather goods they possess. The leather dyes for private use are mostly intended for leather item made using finished leathers, so in this case we talk about retouching dyes or re-painiting. A typical needs could be to repair the color of a sofa or the car interior that has faded with time, in this case you'll need a reparative coloring process.

For Leather Crafters

Another category of leather dyes are those used by leather craftsmen during the creation of their leather goods. In this case it's necessary to color natural leather. Generally leather crafters works on natural veg-tanned leather or sometimes with crust chrome tanned leather. For leather crafters the needs are different than privates, because they will try to get a color and a finish on a natural leather. This operation is generally performed before the creation of the leather item, and to dye a natural leather they can use alcohol-based leather dyes or solvent-based leather dyes.

For Leather Tanneries

The last type of leather dye is the one used in the tanning process. The leather tanning has a very long process and the finished product is obtained only after numerous steps, in the last of which the leather is colored. In this case the colors can be carried out by drums or by spraying machines. The leather dyes used by tanneries are industrial products that can not normally be used if you need to perform a repair or an artisanal coloring, but they are designed to be used through an industrial process.

Leather Dye Among Leather Crafters

Before choosing the leather dye to use, you need to keep in your mind several factors: the type of natural leather to be colored, the finish you want to achieve, the problems that must be avoided once the leather dyeing process has been completed.

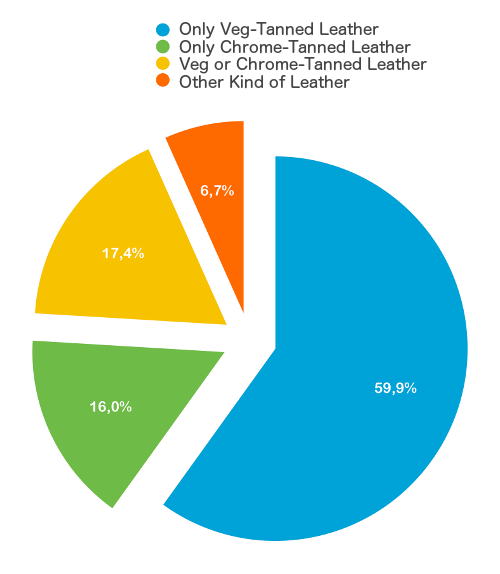

Which kind of leather do leather crafters usually dye?

The Veg Tanned Natural Leather

Natural veg-tanned leather is definitely the most used type among leather crafters. This probably derives from the fact that this type of leather lends itself to several customizations during its working, and can be used to create numerous categories of leather goods. Vegetable tanned leather has its origins from prehistory and perhaps for this reason it still has such a close relationship with man today.

The Chrome Tanned Leather

The chrome-tanning process is a much more recent process, dating back to the end of the nineteenth century. The leathers produced with this process (also called Wet Blue) have greater stability and uniformity. They are often used in the processing of leather items much "softer" even by leather craftsmen, also because they are much easier to work and to color.

The Other Kind of Leathers

In addition to natural leathers, finished leathers can also be used, such as aniline leathers, suede leathers, corrected grain pigmented leathers etc. The choice depends on the type of leather item you want to create. However, these types of leathers are not so popular among the leather crafters, as they do not allow the creation of items with an artisan look. They are rather widespread in the manufacturing industry, and are often those leathers that we find in many of the items that are bought in commercial stores.

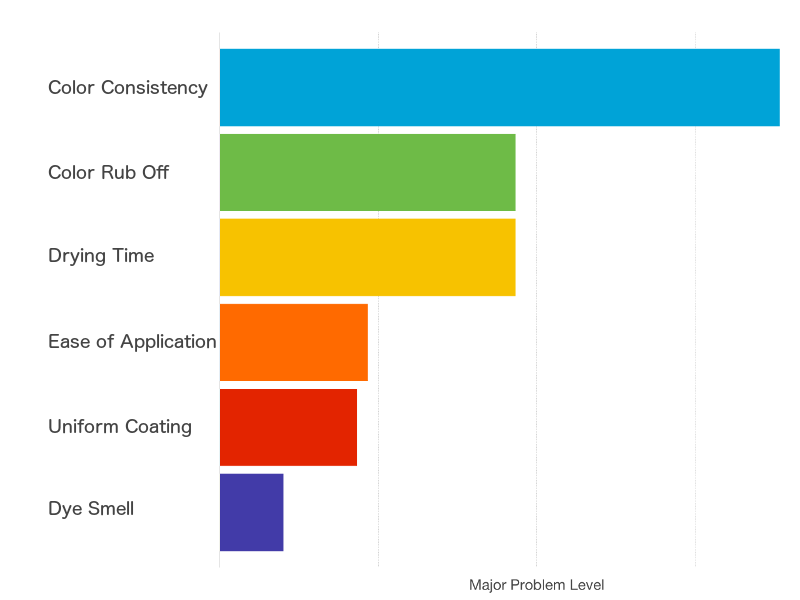

What are the most common problems among leather crafters?

The Leather Dye Color Consistency

The color consistency is a very important topics for leather crafters. When a leather is dyed, they are always looking for a leather dye colors that can give a good coating to the natural leather, a uniform color and at the same time maintaining the natural look of the leather. The leather dye features especially its rapidity of penetration during the leather dyeing process determines the consistency of the color. In fact, too rapid penetration into the leather will lead to a color with less consistency, because color consistency depends on how much the coloring substances remain close to the leather surface.

The Rub Off of Color

Another important aspect that worries leather crafters who use leather dyes is the level of color bonding with natural leather. The problem of color rub off is mainly caused from the fact that the coloring substances contained within the leather dye are not well bonded with the leather fibers. This means that in the leather item life can occur a loose of color. This problem is deeply felt because, for example, in the creation of bags or other leather goods of daily use, this phenomena could cause stains on the clothes worn when they get in contact. Anyway the color rub-off could be limited choosing the right leather dye and eventually using special fixing products as finish operation.

The Leather Dye Drying Time

Drying time is always a very important point for all those who produce leather goods. This is because it influences the timing for the realization of the leather items. However, from the drying time depends different features of the final result. In example a too rapid drying could have a more probable color rub-off. So you always have to look for a leather dye that has a good compromise between drying time and final features.

The Leather Dye Application

One factor to take into consideration when choosing the leather dye to use is the ease of application. Generally the leather dyes are applied by hand from leather crafter, while in the industrial processing it is generally proceeded with spray application. When you're going to produce a colored leather item you should know how to dye natural leather depending on the leather dye you're going to use. The difference lies mainly in the uniformity with the dye distributed on the leather and this determines its final appearance.

The Uniform Coating

When making a colored leather item, it would be generally advisable for the color to be uniform on the leather, avoiding any variations in hues and shades on its surface (except when you want to create a leather goods with a vintage look, in this case a specific leather dyeing techniques will be required). Therefore it is important that the leather dye has the characteristic of remaining almost uniform even if applied several times in the same point. Sometimes you could need to get a lighten color on your leather surface, in this case it could be a good solution to use a leather dye thinner.

The Leather Dye Smell

Smells are also a point on which every leather crafter puts its attention, even if not in first place. Working with more pleasant products, usually facilitates the leather dyeing phase. The smell of a leather dye comes from how many particles are released into the air once we open the bottle. Solvent based or alcohol based dyes are much more volatile products, so they will have a stronger and pungent odor. Water based dyes will certainly have a less strong and more tolerable odor.

Resources from the Blog

Resources from the Academy

Let's learn how to dye natural leather and make it of your favourite color. The process works both on Veg Tanned Leather and on Chrome Tanned Leather.

How to Reduce Leather Dye Transfer

Let’s learn now how to reduce the leather dye rubbing off to the minimum, and how to test it at home.

How to Get a Leather Gloss Finish

Let’s learn now how to get a gloss finish on your leather. To achieve this goal we start from a natural leather that has been dyed using the MAXCRAFT Leather Dye and we will use MAXCRAFT Leather Gloss finish to increase it shininess.

.jpg?width=640&height=428&name=history%20of%20natural%20leather%20(2).jpg)